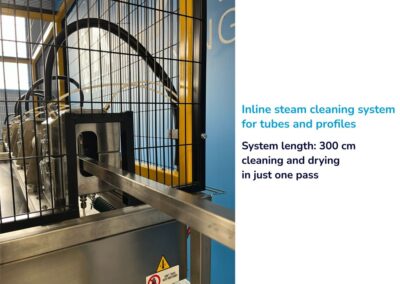

In-Line Steam Cleaning for Profiles

In all types of profile manufacturing—regardless of material or application—in-line cleaning is essential. It ensures product integrity during production and prepares the final part to meet the strict quality standards customers expect.

REA Steam Cleaning specializes in designing in-line steam cleaning systems for profiles and section bars. By relying exclusively on steam technology, our systems deliver superior performance while remaining efficient and environmentally friendly.

Key Advantages of REA Profile Cleaning Systems:

-

High Degreasing Performance – Up to Arcotest level 42

-

Fast Processing Speeds – Synchronizes with production lines up to 98 ft/min

-

Low Water Consumption – Typically under 13 gallons per hour

-

Minimal Wastewater Output – Usually less than 1.5 gallons per hour

-

Reduced Chemical Use – Steam alone is sufficient in most cases

-

Compact Design – Requires less than 3.5 feet of line space

-

Custom-Built Chambers – Tailored for any profile shape, section, or size

-

Interchangeable Chambers – Allows efficient cleaning of different diameters

With REA Steam Cleaning, manufacturers gain a high-performance, eco-friendly, and space-saving solution that keeps production lines running smoothly while meeting the most demanding customer requirements.

Low Water Consumption

With steam cleaning technology, only small amounts of water are required to achieve powerful cleaning results. Water usage is especially minimal when treating smaller profile sections, making the process both efficient and environmentally sustainable.

Benefits of Low Water Consumption

-

Cost Savings – Lower water bills and reduced operating costs.

-

Eco-Friendly – Conserves natural resources and supports sustainability goals.

-

Reduced Wastewater – Minimal water use means less wastewater to manage.

-

Efficient Operation – Delivers powerful cleaning with only small amounts of water.

-

Adaptable Use – Especially effective and efficient when cleaning smaller profile sections.

High Degreasing Performance

One of the key advantages of steam cleaning is its exceptional degreasing capability. The high temperature of the steam effectively breaks down and removes grease, oils, and surface contaminants, ensuring a deep and reliable clean across a wide range of applications.

Benefits of High-Temperature Steam Degreasing

-

Removes Grease & Oils Effectively – Breaks down even the toughest contaminants.

-

Reduces Chemical Dependency – High heat often eliminates the need for harsh degreasers.

-

Eco-Friendly Process – Lower chemical use means safer, greener cleaning.

-

Safe for Equipment – Gentle on components while delivering deep cleaning.

-

Reliable Results – Consistent degreasing performance across applications.

Extremely Compact Footprint

Our in-line steam cleaning systems are engineered with a minimal footprint, keeping all auxiliary components positioned outside the production line. This smart design saves valuable floor space and makes integration simple, even in facilities with limited room.

Benefits of a Compact Footprint

-

Space-Saving Design – Ideal for facilities with limited floor space.

-

Easy Integration – Fits seamlessly into existing production lines.

-

Optimized Layout – Auxiliary components remain outside the production line.

-

Efficient Workflow – Compact design reduces installation complexity.

-

Flexible Use – Suitable for both new and retrofit production setups.

Minimal Wastewater Generation

A major advantage of steam cleaning systems is their ability to produce only a very low volume of wastewater. The small amount generated consists mainly of removed contaminants and light condensed steam, making the process cleaner, safer, and far more sustainable than traditional methods.

Benefits of Minimal Wastewater Generation

-

Eco-Friendly – Reduces environmental impact by limiting wastewater output.

-

Lower Disposal Costs – Cuts expenses for wastewater treatment and handling.

-

Cleaner Operation – Waste consists mainly of contaminants and light condensation.

-

Sustainable Practice – Supports green manufacturing and compliance goals.

-

Safer Workplace – Less water on floors reduces slip hazards for operators.

Seamless Integration

With a compact design and flexible configuration, our steam cleaning systems can be installed directly into existing production lines—even in tight spaces. Installation requires only minimal modifications, allowing customers to see immediate benefits from day one.

Eco-Friendly by Design

REA Steam Cleaning systems are a true alternative to solvent-based cleaning—we never use solvents. Steam technology provides a sustainable, environmentally responsible solution without sacrificing cleaning performance.

Minimal Detergent Use

In the rare cases where detergent is required, our systems use a continuous recycling process that keeps consumption exceptionally low—typically less than 1.5 gallons per day. This not only saves money but also reduces waste.

Highly Versatile

Our proprietary interchangeable chamber system allows for quick adaptation to different profile diameters. With changeover times of under 5 minutes, production remains fast, efficient, and uninterrupted.

Key Benefits at a Glance

-

Seamless Integration – Compact design installs easily with minimal modifications.

-

Eco-Friendly – 100% solvent-free, sustainable cleaning solution.

-

Minimal Detergent Use – Recycling process keeps consumption under 1.5 gallons/day.

-

Highly Versatile – Interchangeable chambers adapt in less than 5 minutes.