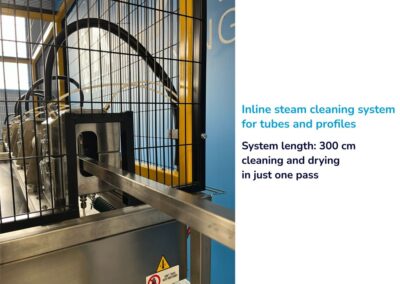

In all types of profile manufacturing—regardless of material or application—in-line cleaning is essential. It plays a crucial role both during production and in preparing the final product to meet quality standards expected by customers.

REA Steam Cleaning specializes in designing in-line cleaning systems for profiles and section bars, exclusively using steam technology. Steam offers several key advantages:

-

High degreasing performance (up to Arcotest level 42)

-

Fast cleaning speeds, synchronized with the production line—up to 98 feet per minute

-

Low water consumption, typically under 13 gallons per hour

-

Minimal wastewater generation, usually less than 1.5 gallons per hour

-

Very low detergent usage—in most cases, steam alone is sufficient

-

Compact system footprint, generally requiring less than 3.5 feet of line space

-

Custom-built washing chambers, designed to fit any profile shape, section, or size

-

Interchangeable chambers for efficient treatment of different diameters

Low water consumption

In the case of steam cleaning, small quantities of water are used, especially when the profile section is small.

High Degreasing Performance

An inherent advantage of steam cleaning, thanks to the high temperature of the steam, is its exceptional ability to remove grease and contaminants.

Extremely Compact Footprint

All our in-line cleaning systems are designed with a minimal footprint, as all auxiliary components are positioned outside the production line.

Minimal Wastewater Generation

A key advantage of steam cleaning systems is the very low volume of wastewater produced—consisting primarily of removed contaminants and a small amount of condensed steam.

Seamless Integration

Thanks to their compact design and flexibility, our systems can be easily installed even in tight spaces on existing production lines, requiring only minimal modifications. This results in immediate benefits for the customer, starting from the installation phase.

Eco-Friendly by Design

Our systems are a genuine alternative to solvent-based cleaning—no solvents are used, ever. Steam cleaning offers a sustainable, environmentally responsible solution without compromising performance.

Minimal Detergent Use

When detergent is needed, it is continuously recycled within the system, keeping consumption extremely low—typically less than 1.5 gallons per day.

Highly Versatile

Our proprietary interchangeable chamber system enables fast adaptation to different profile diameters, with changeover times of less than 5 minutes.