One of the main objectives of food manufacturers is the constant improvement of sanitization to reduce the risk of potential product contamination

Modular belts can be highly problematic, as bacteria and microorganisms are present in the mesh. Manual cleaning is labor-intensive and most likely require chemicals and vast amounts of water.

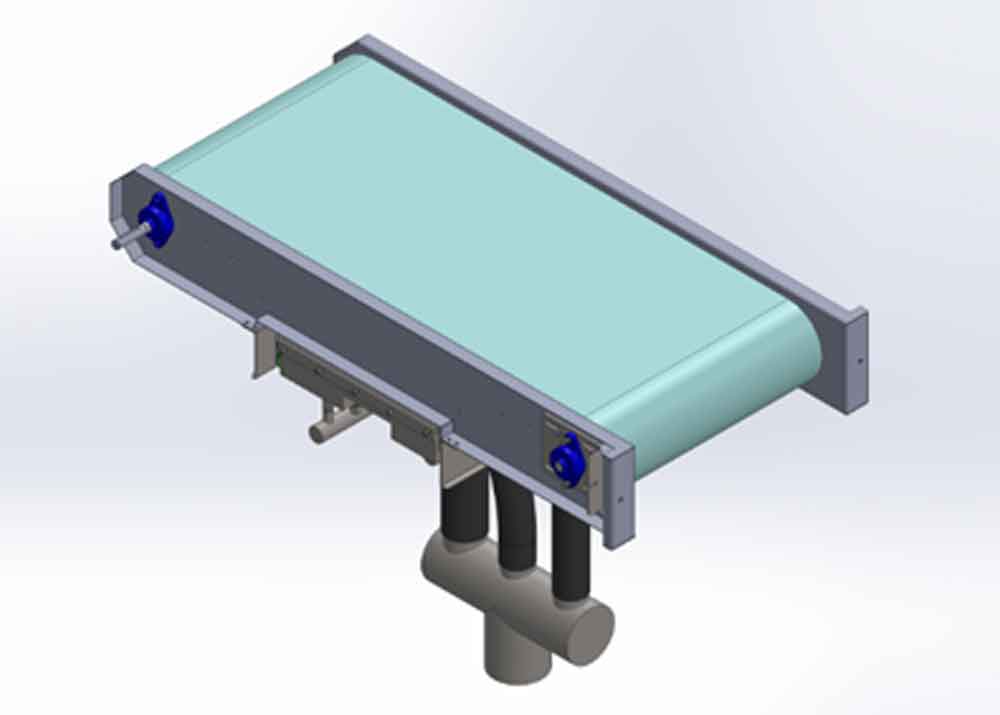

Jolly D Belt Cleaner

This system is ideal for cleaning and sanitizing modular belts during processing. The belt cleaner is equipped with upper and lower cleaning tool that allow the washing of both faces of the modular belt at the same time. Available functions include: steam, steam + water, with continuous suction to leave the belt dry. Download the Data Sheet

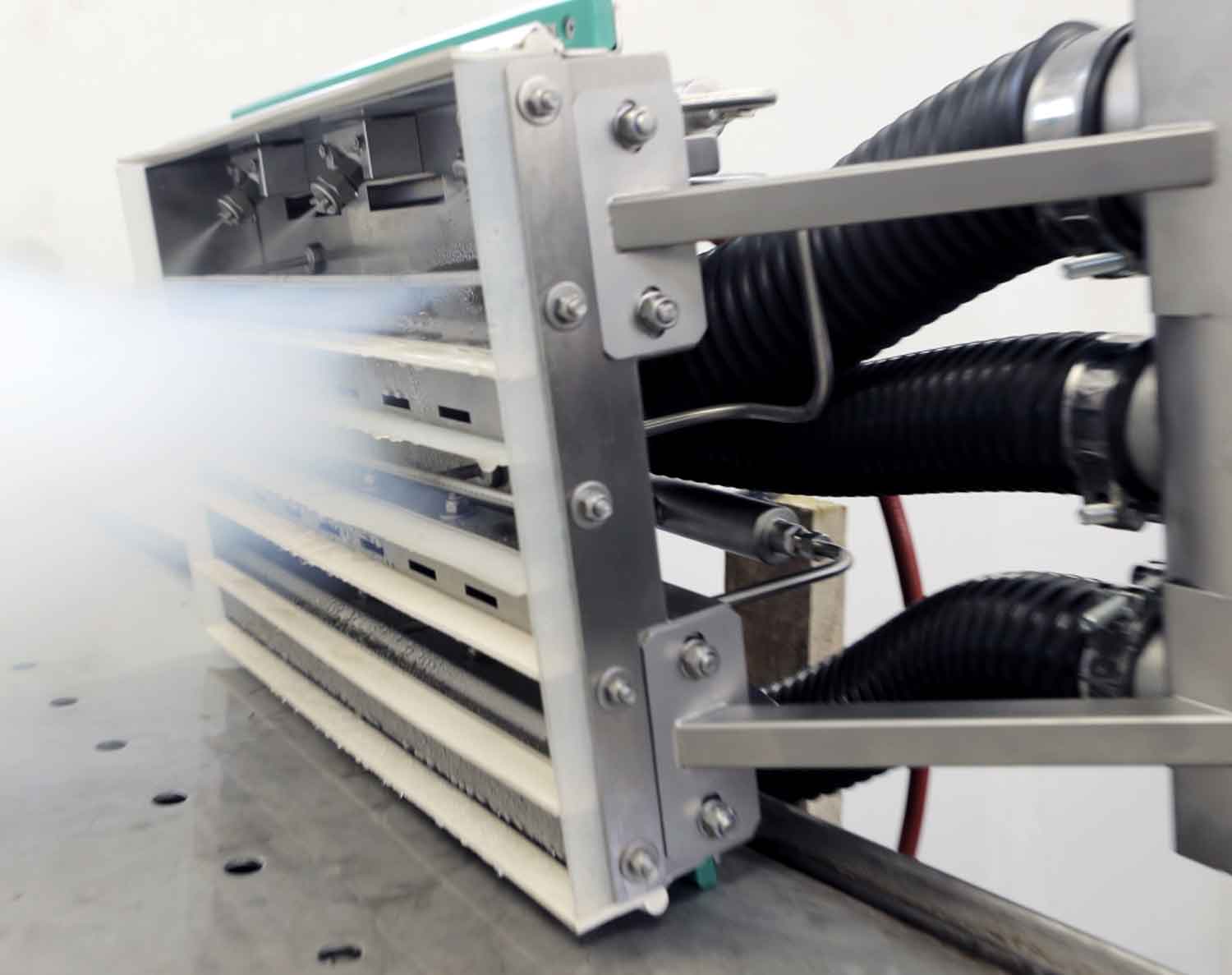

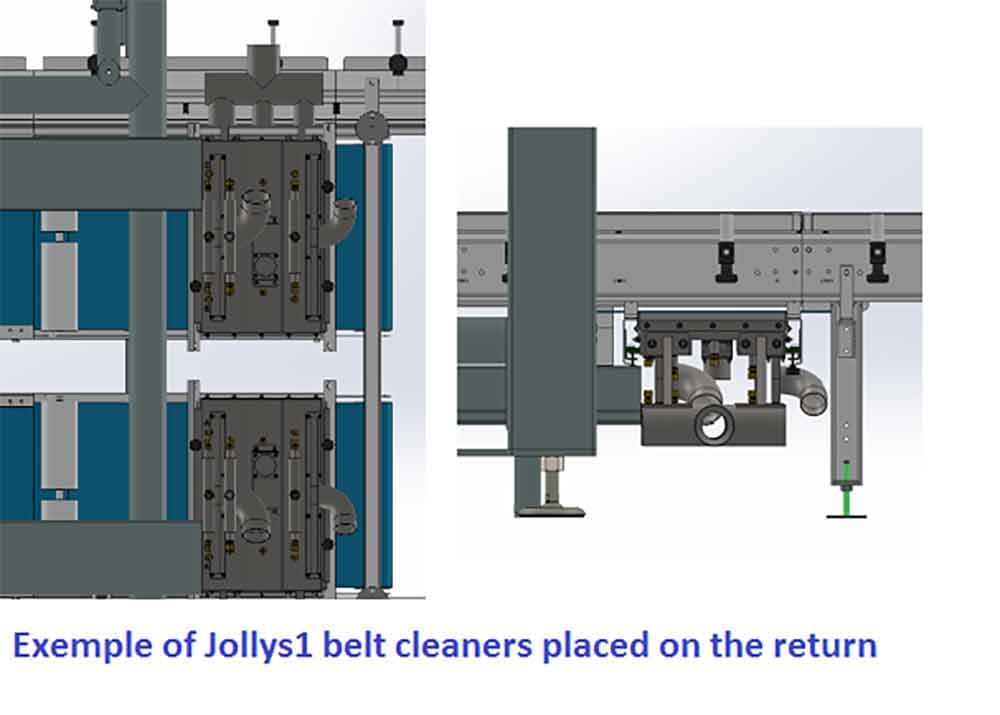

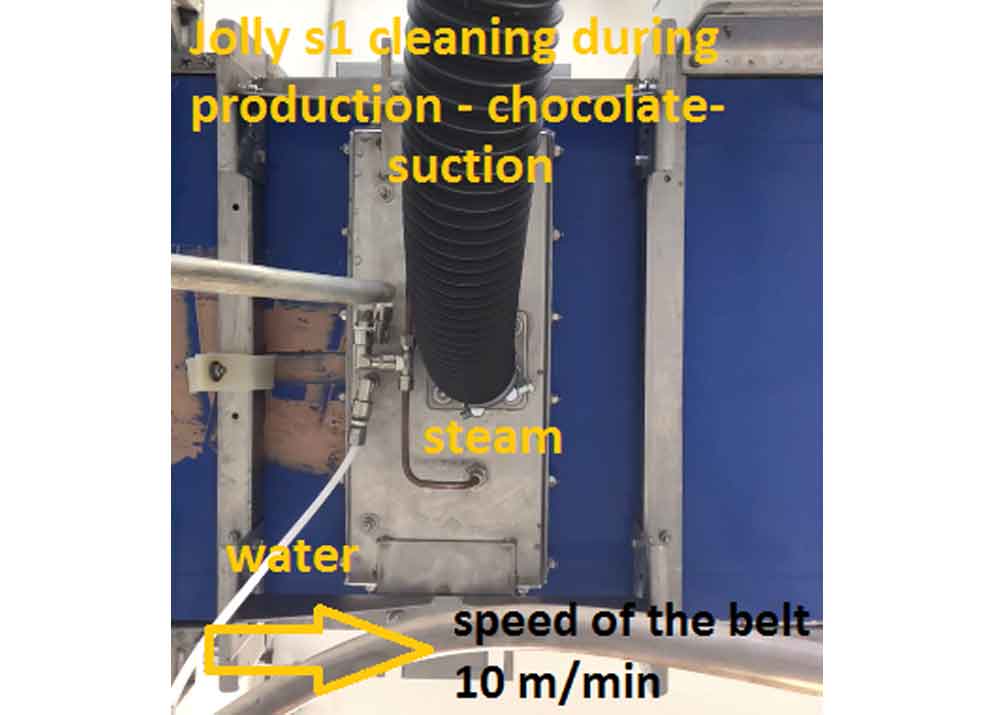

Automatic steam belt cleaners – Jolly S2 models for smooth belts, Jolly D for modular belts.

These models do not require the presence of an operator and can be used continuously during production. They are available for both smooth and modular belts. Jolly S2 is equipped with 2 washing chambers. The first chamber combines steam and water for the removal of visible contamination, the second sanitization with steam only.

The suction on both chambers allows to leave a dry surface.

Advantages include:

- Eliminating the time and labor costs for cleaning the conveyor belt.

- Always having a conveyor belt that is sanitized during production, a mitigating factor in providing your customers a finished product of superior quality. Download the Data Sheet

Environmental sustainability and innovation.

The REA Tornado system is designed to allow belt cleaning after production of the without an operator of the use of chemicals, using only the 145 PSI pressure of the steam and its high temperature. Greater than 212 ° F at the moment of impact.

Water consumption is negligible (on average 5.3 gallons / hour), the steam temperature makes the system detergent free and provides savings in chemical, water disposal and labor costs.

The high-speed rotation of the steam nozzle produces a mechanical action that immediately removes all residue. Once the visible residue has been removed, the second cleaning round allows for total sanitization.

- Entirely built in AISI 304 stainless steel that will not damage the belt.

- Will work with any belt width

- It can wash, sanitize and dry in a single operation

- It can be applied on multiple tapes, even if they differ in width, without tools and in a few minutes

- Programmable washing is done with an intuitive touch screen interface.

- The steam temperature produces a dry belt after washing

- Totally safe to operate and the residual water is collected in a tank

VDA is currently the most economical and effective system for cleaning and sanitizing belts in the food industry. Download the Data Sheet

Steamatic

Ideal for chain belts (Flexlink type), it moves easily from one belt to another. It is constructed of to provide multiple chambers that allows you to use steam or steam and water, combined with suction to leave the belt clean and dry.

There is no contact between the belt and the belt cleaner. This ensures a belt that is always clean with no accumulation of bacteria or dirt.

- Entirely built in AISI 304 stainless steel (without brushes) it does not damage the belt.

- Available in widths 2.55 inches, 3.35 inches, 4 inches, and 7.1 inches. Others widths are available on request

- Mounts quickly on any belt, without tools or modifications to the frame.

- Total extraction of steam and residual water, produces a dry, clean belt.

- Safe for the operator, no steam or water leaks.

- Possibility to use steam only, or steam + water, depending on the type of contamination. Download the Data Sheet

Steamatic is currently the simplest, most effective and economical system for cleaning and sanitizing belts in the food, pharmaceutical or cosmetic sectors.